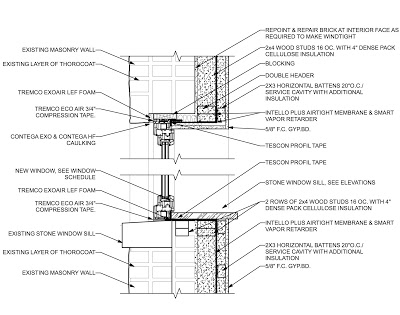

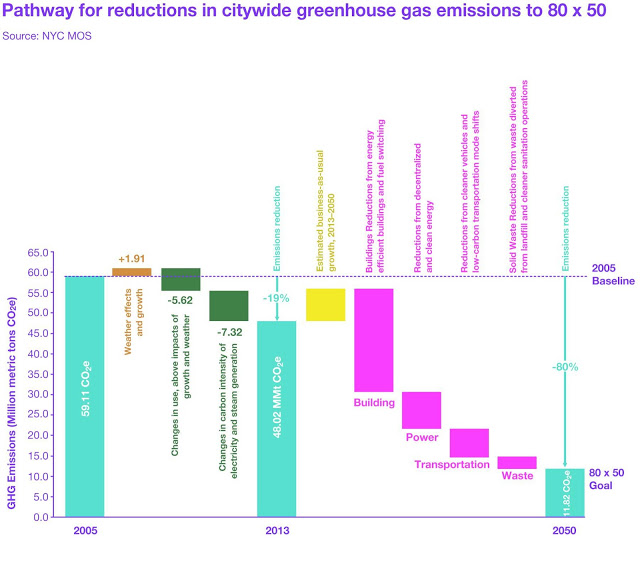

Air-tightness is a critical element of all energy efficient buildings. Air infiltration from the exterior is a major factor in heat loss (or in the summer the loss of cooled air in the building). This is independent of the level of thermal insulation in the structure. Air leaks also will allow moisture from the conditioned space into the insulation and building structure. This may lead to damage within the construction assemblies. To combat these issues the Passive House standards require a level of airtightness that allows a maximum of maximum of 0.6 air changes per hour at 50 Pascals pressure (ACH50), as verified by an onsite pressure test (in both pressurized and depressurized states).

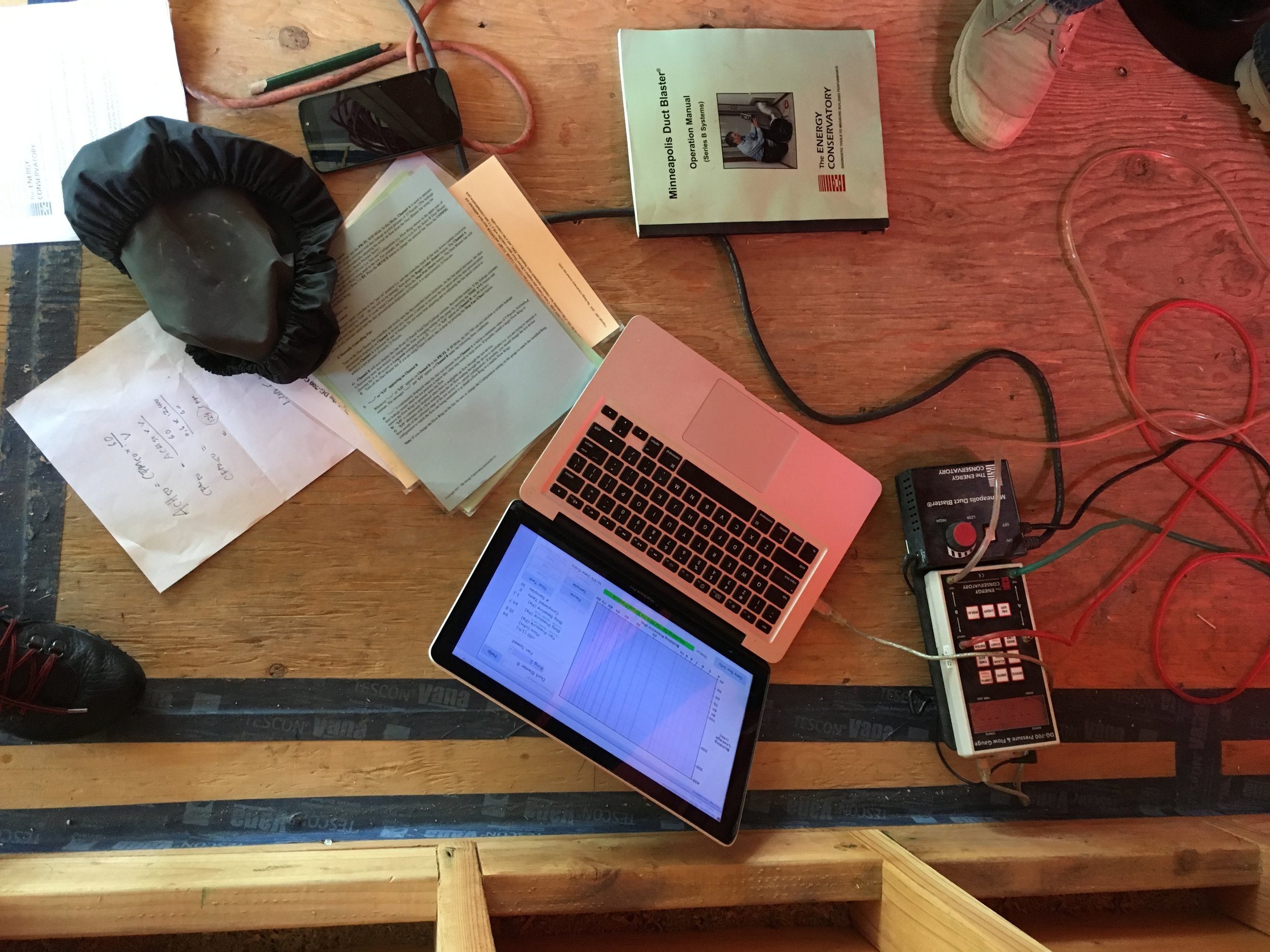

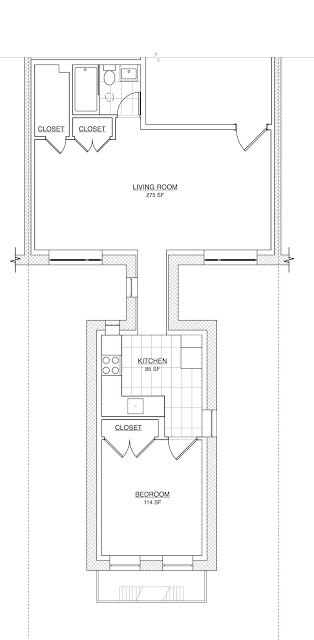

For our CT-3 Connecticut Passive House we carried out the blower door test on Saturday and passed with 0.5 air changes per hour. It is a small building which makes it harder to achieve the air tightness. We are very happy to have achieved this important goal. A big thank you to Andreas Benzing of A.M. Benzing Architects pllc for conducting the test.

During the depressurization we inspected all exterior surfaces for air leaks. We found two big ones and a few smaller areas which needed additional tapping. They will be sealed this week and improve the air-tightness even more. The images attached show the testing, calculation the air change rate and the search for leaks.